Budget-Friendly litho printing Solutions for Your Business

Budget-Friendly litho printing Solutions for Your Business

Blog Article

A Comprehensive Guide to Understanding Litho Printing Techniques

The world of litho printing, a method stemming from the late 18th century, is an interesting blend of background, art, science and development. This extensive guide will certainly unravel the intricacies of this printing technique, from the composition of litho inks to the challenges faced in contemporary applications. As we venture into the details of lithography, the importance of automation and sustainability in guaranteeing its future relevance ends up being increasingly clear. Stay with us as we journey right into the fascinating world of litho printing.

The Historical Advancement of Litho Printing

The historic trajectory of litho printing, a crucial technology in the realm of communication, is a fascinating story of human resourcefulness. The procedure advanced with the development of the rotating press, which substantially raised efficiency. Each phase of litho printing's advancement showcases humankind's relentless quest of effectiveness and high quality in visual communication.

Deciphering the Science Behind Litho Printing Inks

Moving on in the expedition of litho printing techniques, the focus now moves to the science behind litho printing inks. The composition of these inks, their drying process, and color mixing methods develop the foundation of this intricate art type. Understanding these aspects is vital to grasping the craft and attaining the preferred print results.

Structure of Litho Inks

In lithographic printing, the basic role of litho inks can not be overemphasized. The make-up of litho inks differs depending upon its objective, however generally, they include 2 major elements - lorries and pigments. Pigments, the color-providing aspects, are finely ground bits suspended in the car, a liquid that brings the pigment onto the printing surface. The car is a complicated mix of resins, solvents, and oils, which influence the ink's drying out time, attachment, and gloss. In addition, different ingredients exist to boost specific residential or commercial properties like circulation, drying, and resistance to environmental impacts. Each component plays a critical component in the final print's high quality, making the specific formula of litho inks an intricate science.

Ink Drying Process

From the composition of litho inks, focus turns to the interesting procedure of ink drying out. Two primary methods are utilized in litho printing: oxidative drying and absorption. Absorption, on the other hand, entails the ink permeating into the paper fibers, which is a quicker procedure yet can lead to much less lively shades.

Color Combining Techniques

While the drying out procedure plays a crucial role in litho printing, the science of shade blending techniques holds equivalent relevance. The scientific research behind litho printing inks likewise takes into account the openness of the ink, which impacts how shades overlay and mix.

The Art and Design Elements in Litho Printing

Litho printing takes a breath life right into art and style via its unique elements. Litho printing fits a selection of shades, allowing artists to create lively and vibrant prints. This mix of precision and flexibility makes litho printing a preferred option for numerous artists and developers.

Modern Applications of Litho Printing Strategies

Litho printing strategies have located substantial usage in the modern commercial sector. Its impact and importance proceed to grow with the development of new innovations and modern technologies in the area. This area will discover these modern applications and the transformative role they play in the printing sector.

Business Litho Printing Makes Use Of

In today's digital age, one might question the relevance of traditional printing approaches. Yet, litho printing continues to be a crucial part of the commercial field. High-volume printing tasks, such as the manufacturing of books, papers, and product packaging, rely upon litho printing for its ability to deliver exceptional image top quality and expense efficiency. The process, which includes transferring a tattooed photo from a plate onto a rubber blanket find and afterwards to the printing surface area, uses unmatched consistency. This makes it excellent for work calling for a large print run. Litho printing likewise supplies a broad color spectrum, remarkable to that of electronic printing. This makes it the go-to option for projects that require vivid, top notch color recreation.

Technologies in Litho Printing

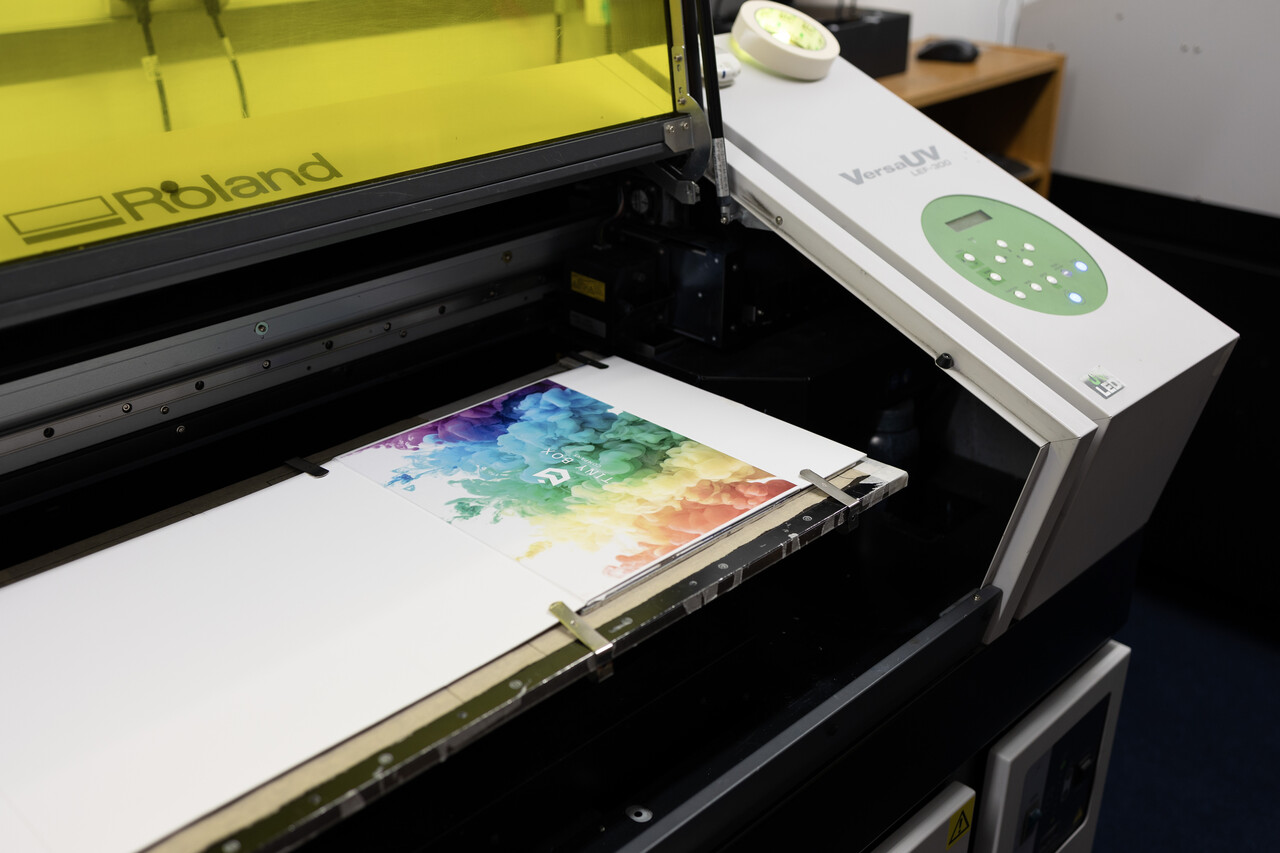

Pressing the borders of typical methods, contemporary improvements have fueled a host of advancements in litho printing. One prominent advancement is electronic litho printing, which combines the merits of digital innovation with her comment is here litho's top quality result. These advancements emphasize the enduring significance of litho printing in the contemporary globe.

Exploring the Process of Litho Printing: Step by Action

Obstacles and Solutions in Contemporary Litho Printing

In spite of the precision and custom that litho printing happily supports, it is not without its set of modern challenges. One of the most widespread problems consist of the high first configuration cost, problem in printing variable data, and ecological worries as a result of chemical use. Nonetheless, solutions are becoming technology progresses. Digital litho printing permits affordable short runs and very easy modification, dealing with the problem of variable information. Environmentally-friendly inks and safer plate-making processes minimize environmental concerns. Additionally, improvements in automation have actually lowered labor expenses, better equalizing the lithography process. Therefore, while there are challenges, the litho printing sector is proactively adjusting to satisfy them head-on, ensuring its importance in the future.

Final thought

In verdict, litho printing, with its abundant background and scientific complexities, holds a substantial area in the print market. As the overview exposes, it's a synthesis of art and technology, with contemporary improvements ensuring its importance. Nevertheless, the sector encounters obstacles that require cutting-edge remedies, with a concentrate on automation and sustainability. The future of litho printing rests on its ability to adapt to these changing demands, verifying its enduring value in a progressing market.

Report this page